Resistance welding electrodes for non-ferrous metals

For resistance welding of non-ferrous metals electrodes are madeof tungsten (W), molybdenum (Mo) or other refractory alloys due tomuch better properties during work in high temperatures.Compositeelectrodes, where the shank supplies electricity and dissipates thegenerated heat, and the electrode tip made of W or Mo takes partin the welding process, is a very good choice for most applications.

The advantages of refractory metals electrodes:

*Stable hardness at high temperatures

*Low thermal conductivity

*Low adhesion

*Low chemical reactivity with other materials

The above-mentioned advantages significantly contribute to thestabilization of the welding process, and hence to the improvementof production efficiency and the extension of the life of a singleelectrode.

Materials properties

Tungsten (W)

*Composed in more than 99.9% pure tungsten

*The highest melting point among metals (3387°C).

*Very high hardness at both in room and high temperatures

*Sensitive to mechanical and thermal shock and cracking

*Low reactivity with other metal components.

Molybdenum (Mo)

*Composed in more than 99.9% pure molybdenum

*One of the highest melting point among metals (2623°C)

*More resistant to mechanical and thermal shock than W

*Less hardness in room and high temperatures compared to W

*Low reactivity with other metal components.

*Electrical and thermal properties comparable to tungsten.

Copper-tungsten alloy (Cu25W75).

*Alloy made of copper and tungsten.

*Characterized by moderate properties between copper alloysand tungsten.

*Moderate hardness at high temperature.

*Better electrical conductivity than tungsten and molybdenum.

Silver-tungsten alloy (Ag35W65).

*Alloy made of silver and tungsten.

*Like the CuW alloy,AgW is characterized by moderate

*hardness at high temperatures and electrical conductivity

*Usually, it consists of 35%Ag and 65% with W.

*Used for welding stainless steel and / or nickel foils.

The use of tungsten and molybdenum electrodes:

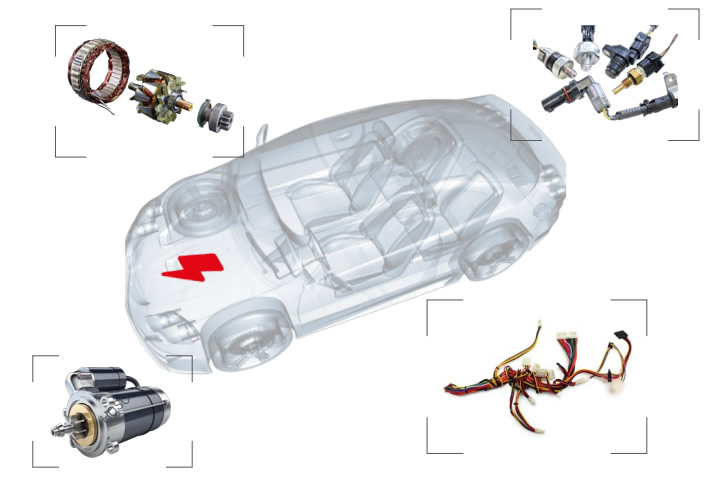

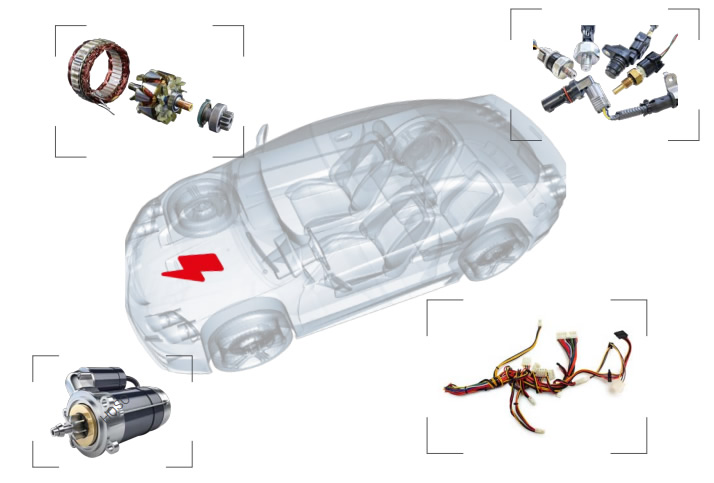

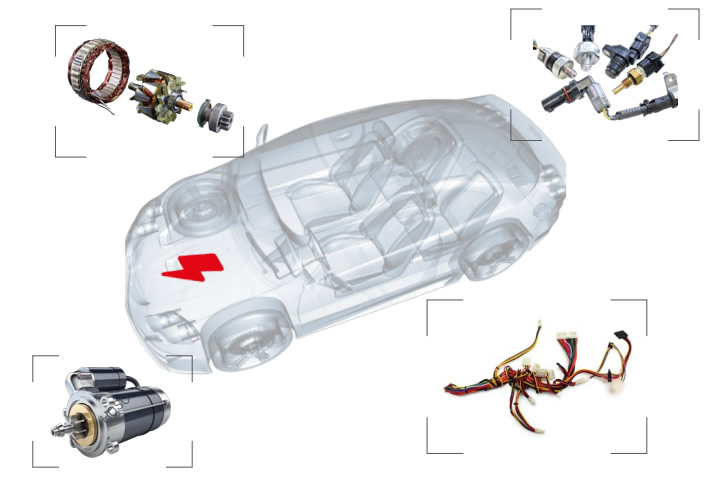

The electrodes are mainly used for welding electrical parts used in the production of cars. Other industries using this type of electrodes include: electronics and household appliances.

The use of tungsten and molybdenum electrodes:The electrodes are mainly used for welding electrical parts used in the production of cars. Other industries using this type of electrodes include: electronics and household appliances.

The use of tungsten and molybdenum electrodes:The electrodes are mainly used for welding electrical parts used in the production of cars. Other industries using this type of electrodes include: electronics and household appliances.

The use of tungsten and molybdenum electrodes:The electrodes are mainly used for welding electrical parts used in the production of cars. Other industries using this type of electrodes include: electronics and household appliances.

The use of tungsten and molybdenum electrodes:The electrodes are mainly used for welding electrical parts used in the production of cars. Other industries using this type of electrodes include: electronics and household appliances.

The use of tungsten and molybdenum electrodes:

The use of tungsten and molybdenum electrodes: The use of tungsten and molybdenum electrodes:

The use of tungsten and molybdenum electrodes: