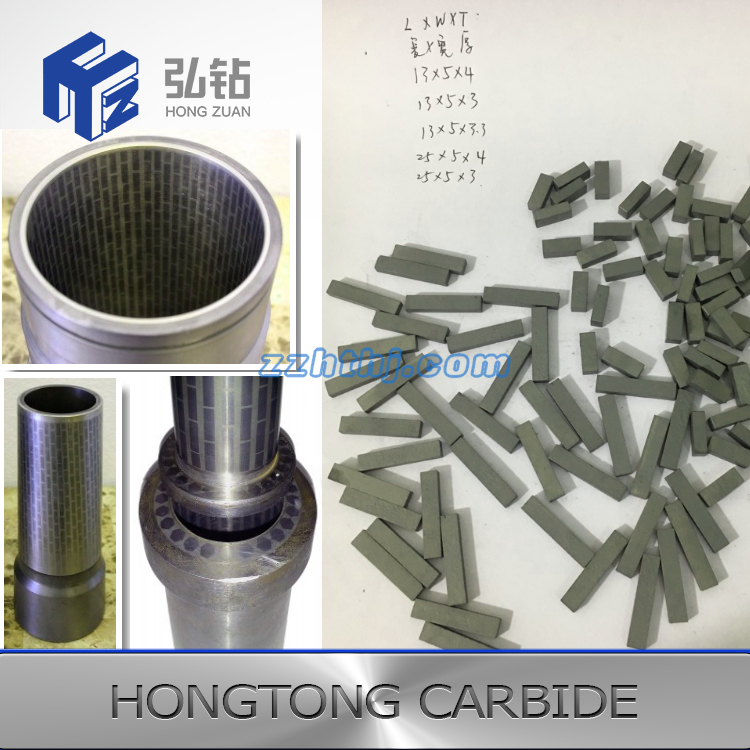

To meet a variety of the most demanding drilling conditions, we offer various sizes and shapes of tungsten carbide inserts for hard-facings in different options for your stabilizers. Each carbide insert is tailored to your specific needs and our expert application ensures exceptional resistance to wear and tear, prolonging the life of your stabilizers. Such as HF2000, geothermal hard-facing utilizes tungsten carbide bricks, brazed to the stabilizer blade and surrounded by tungsten impregnated composite rod; HF3000, A hard-facing method that applies the maximum amount of premium tungsten carbide on any wear surface. It can be applied in varied thickness and uses tungsten carbide inserts to maximize abrasive and impact durability; and so on.

| Shape | Dimensions (mm) |

| Rectangular | 6 x 5 x 3 |

| Rectangular | 6 x 5 x 4 |

| Rectangular | 13 x 5 x 3 |

| Rectangular | 13 x 5 x 4 |

| Rectangular | 20 x 5 x 4 |

| Rectangular | 25 x 5 x 3 |

| Rectangular | 25 x 5 x 4 |

| Round | 6-20 diameter |

| Serrated | 10-20 diameter |

| Grade | Density /Cm 3 | Bend Strength N/mm 2 | Hardness HRA |

| YG6 | 14.8-15.1 | ≥1770 | ≥90 |

| YG8 | 14.6-14.9 | ≥1840 | ≥89 |

| YG11 | 14.4-14.7 | ≥2700 | ≥88.5 |

| YG11C | 14.4-14.7 | ≥2800 | ≥86.5 |

| YN6 | 14.7-15.0 | ≥1800 | ≥90.5 |

| YN8 | 14.4-14.7 | ≥1900 | ≥89 |

| YN12 | 14.1-14.4 | ≥2100 | ≥88 |

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.