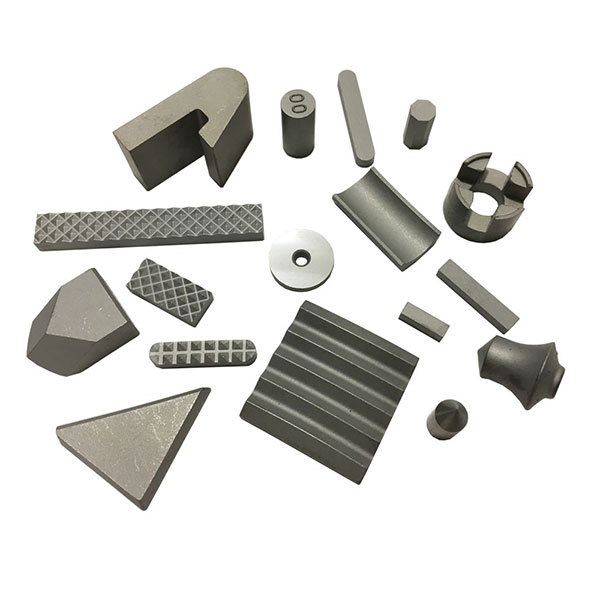

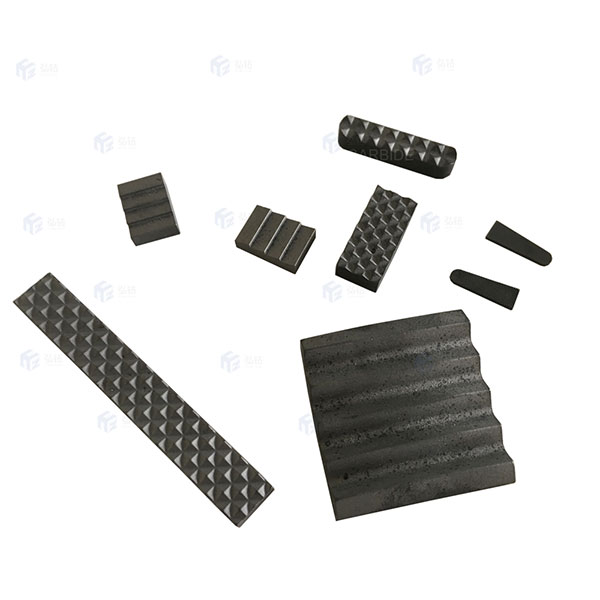

As the tungsten carbide material has high hardness and strength, its wear resistance is very good. They are widely used in many different industries and applications, even some new application is happening every day. We have much experience and know-how engineers, welcome to talk to us if there are any OEM or ODM request.

| Grade | Equal to ISO Category Number | Performance | Performance&application recommended | ||

| Density G/Cm 3 | Bend Strength N/mm 2 | Hardness HRA | |||

| YG3 | K01 | 14.9-15.3 | ≥1180 | ≥90.5 | Sand-blasting nozzles qualified for fine turning and half-fine turning when cast iron, non-ferrous metal, alloys as well as non-alloy materials cutting consecutively. Can make wire drawing of steel and non-ferrous metal. Also qualified for sand-blasting n |

| YG3X | K01 | 15.1-15.4 | ≥1300 | ≥91.5 | |

| YK05 | 14.95 | 2500 | 90.5 | Mostly used as the buttons of small and bits medium sized percussion | |

| YG8C | 14.8 | 2400 | 88.5 | and as the inserts of rotary prospecting bits to cut soft and | |

| medium hard formations. | |||||

| YG6 | 14.95 | 1900 | 90.5 | For coring crowns,electric coal drill bits, coal cutting picks,oil | |

| cone bits and scraping knife bits,used in coal geological prospecting, | |||||

| mining and oil well boring. | |||||

| YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | |

| YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG8 | K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| YG10X | 14.5 | 2400 | 91.5 | Fine grain alloy, good wear resistance,Used for processing hard | |

| wood, veneer board,PCB,PVC and metals. | |||||

| YG11 | 14.4 | 2600 | 88.5 | Forming or stamping dies for metal powders and nonmental powders. | |

| YG11C | K40 | 14.4 | 2700 | 86.5 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium |

| hard, hard and very hard formations. | |||||

| YG15 | K40 | 14 | 2800 | 87.5 | For fabricating drawing dies of steel tubesand rods under high |

| compressibility ratio;punching,stamping,forging tools under large stress. | |||||

| YG15C | 14 | 3000 | 85.5 | For oil cone dril bits, for medium soft and medium-hard rocks. | |

| YG16C | 13.9 | 2900 | 85.5 | Impact resistance, hot&forging dies etc. | |

| YGH40 | 13.5-13.9 | ≥2450 | ≥83.0 | Mainly for making hot dies. | |

| YG20 | 13.5 | 3200 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical | |

| instruments, battery jars,small sized steel balls,screws,screw caps. | |||||

| YG18C | 13.7 | 3100 | 84.5 | Impact resistance forging dies,hot-press forging dies and rollers. | |

| YG20C | 13.5 | 3300 | 83.5 | Dies for wear resistant or impact resistant application. | |

| YG22C | 13.3 | 3500 | 83 | Nut forming dies and high impact resistance forging dies. | |

| YG25C | 13.1 | 3600 | 82.5 | Stainless bolt header dies and rollers. | |

| YT15 | P10 | 11.1-11.6 | ≥1180 | ≥91.0 | Qualified for rough machining, semi-finish machining and finish machining during consecutive machining of carbon steel and alloy steel. |

| YT14 | P20 | 11.2-11.8 | ≥1270 | ≥90.5 | Qualified for rough machining for rough face of carbon steel and alloy steel, half process during discontinuity cutting. |

| YT5 | P30 | 12.5-13.2 | ≥1430 | ≥89.5 | Qualified for rough machining for rough face of carbon steel and alloy steel and discontinuity cutting. |

There are hundreds of thousands of applications, so I cannot give you more information here. However, if you have any comments and advice for any items, welcome to leave me message, I will talk to you as soon as possible.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.