Tungsten Carbide wire drawing nibs was pressed into steel holder, to work as a wire drawing die, which was widely used in the production of wire, cable, tube, and other related products. As the parameters of tungsten carbide, the dies can last longer time and need less replacement and maintain, which make it more profitable for users. As there’re many different kinds of wire/tube/rod products, there’re various kinds of different wire drawing dies and nibs, including types S11 series, S12 series, S13 series, W series, WTA series, R series, etc.

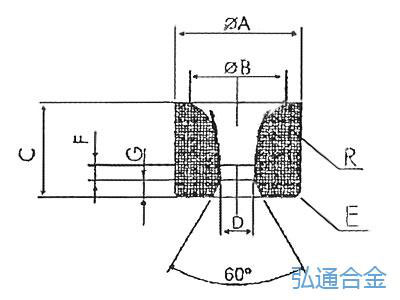

| Type | A | B | C | D | E | F | G | R |

| WTA 001 | 30.00 | 23.00 | 24.00 | 08.00 | 1.0×45* | 04.00 | 04.00 | 10.00 |

| WTA 002 | 30.00 | 23.00 | 24.00 | 09.00 | 1.0×45* | 04.00 | 04.00 | 10.00 |

| WTA 003 | 30.00 | 23.00 | 24.00 | 10.00 | 1.0×45* | 04.00 | 04.00 | 10.00 |

| WTA 004 | 30.00 | 23.00 | 24.00 | 11.00 | 1.0×45* | 04.00 | 04.00 | 10.00 |

| WTA 005 | 30.00 | 23.00 | 24.00 | 12.00 | 1.0×45* | 04.00 | 04.00 | 10.00 |

| WTA 006 | 35.00 | 26.00 | 25.00 | 10.00 | 1.0×45* | 04.00 | 04.00 | 12.00 |

| WTA 007 | 35.00 | 26.00 | 25.00 | 11.00 | 1.0×45* | 04.00 | 04.00 | 12.00 |

| WTA 008 | 35.00 | 26.00 | 25.00 | 12.00 | 1.0×45* | 04.00 | 04.00 | 12.00 |

| WTA 009 | 35.00 | 26.00 | 25.00 | 13.00 | 1.0×45* | 04.00 | 04.00 | 12.00 |

| WTA 010 | 35.00 | 26.00 | 25.00 | 14.00 | 1.0×45* | 04.00 | 04.00 | 12.00 |

| WTA 011 | 35.00 | 26.00 | 25.00 | 15.00 | 1.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 012 | 40.00 | 32.00 | 28.00 | 12.50 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 013 | 40.00 | 32.00 | 28.00 | 14.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 014 | 40.00 | 32.00 | 28.00 | 15.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 015 | 40.00 | 32.00 | 28.00 | 16.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 016 | 45*.00 | 37.00 | 28.00 | 15.50 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 017 | 45*.00 | 37.00 | 28.00 | 17.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 018 | 45*.00 | 37.00 | 28.00 | 18.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 019 | 45*.00 | 37.00 | 28.00 | 19.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 020 | 45*.00 | 37.00 | 28.00 | 20.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 021 | 50.00 | 40.00 | 30.00 | 21.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 022 | 50.00 | 40.00 | 30.00 | 22.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 023 | 50.00 | 40.00 | 30.00 | 24.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 024 | 50.00 | 40.00 | 30.00 | 25.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 025 | 50.00 | 40.00 | 30.00 | 27.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 026 | 55.00 | 45*.00 | 30.00 | 28.50 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 027 | 55.00 | 45*.00 | 30.00 | 30.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 028 | 60.00 | 45*.00 | 30.00 | 30.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 029 | 60.00 | 45*.00 | 30.00 | 33.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 030 | 65.00 | 50.00 | 30.00 | 34.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 031 | 65.00 | 50.00 | 30.00 | 36.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 032 | 65.00 | 50.00 | 30.00 | 38.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 033 | 70.00 | 60.00 | 30.00 | 38.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 034 | 70.00 | 60.00 | 30.00 | 40.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 035 | 75.00 | 65.00 | 30.00 | 42.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 036 | 75.00 | 65.00 | 30.00 | 44.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 037 | 80.00 | 70.00 | 30.00 | 46.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 038 | 80.00 | 70.00 | 30.00 | 48.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 039 | 85.00 | 75.00 | 30.00 | 50.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 040 | 85.00 | 75.00 | 30.00 | 52.00 | 2.0×45* | 06.00 | 05.00 | 12.00 |

| WTA 041 | 90.00 | 80.00 | 32.00 | 53.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 042 | 90.00 | 80.00 | 32.00 | 55.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 043 | 95.00 | 85.00 | 32.00 | 57.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 044 | 95.00 | 85.00 | 32.00 | 60.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 045 | 100.0 | 90.00 | 35.00 | 64.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 046 | 100.0 | 90.00 | 35.00 | 66.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 047 | 110.0 | 95.00 | 35.00 | 70.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 048 | 110.0 | 95.00 | 35.00 | 73.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 049 | 120.0 | 105.0 | 35.00 | 76.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| WTA 050 | 120.0 | 105.0 | 35.00 | 78.00 | 2.0×45* | 07.00 | 05.00 | 12.00 |

| Grade No. |

Density (g/cm3) |

HRA |

T.R.S (Mpa) |

Application |

| YG3X | 14.9 | ≥91.5 | ≥1300 | For drawing non-ferrous metal wire and stainless-steel wire etc. |

| YG6 | 14.8 | ≥90.0 | ≥2150 | For drawing steel wire and stainless-steel wire etc. |

| YG6X | 14.8 | ≥92.0 | ≥1860 | For drawing nonferrous metal wire, steel wire, stainless steel wire. Good wear resistance and high toughness. |

| YG8 | 14.8 | ≥89.5 | ≥2320 | For drawing steel wire, stainless steel wire. Good general performance. |

| YG11 | 14.4 | ≥88.5 | ≥2420 |

For fabricating drawing dies of steel tubes and rods under high compressibility ratio; punching, stamping, forging tools under large stress. |

1. Tungsten carbide with high hardness, high wear resistance and high red hardness, at 550℃ still maintain more than 56HRC hardness.

2. Has a high modulus of elasticity, generally is (4~7)×104kg / mm2, and excellent rigidity at room temperature.

3. Have a high compressive strength which is greater than 6000MPa.

4. Have good resistance to oxidation and corrosion resistance, acid resistance, alkali resistance and high temperature not easily oxidized.

5. Has a low coefficient of thermal expansion, suitable for manufacturing high, precision, sharp die.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.