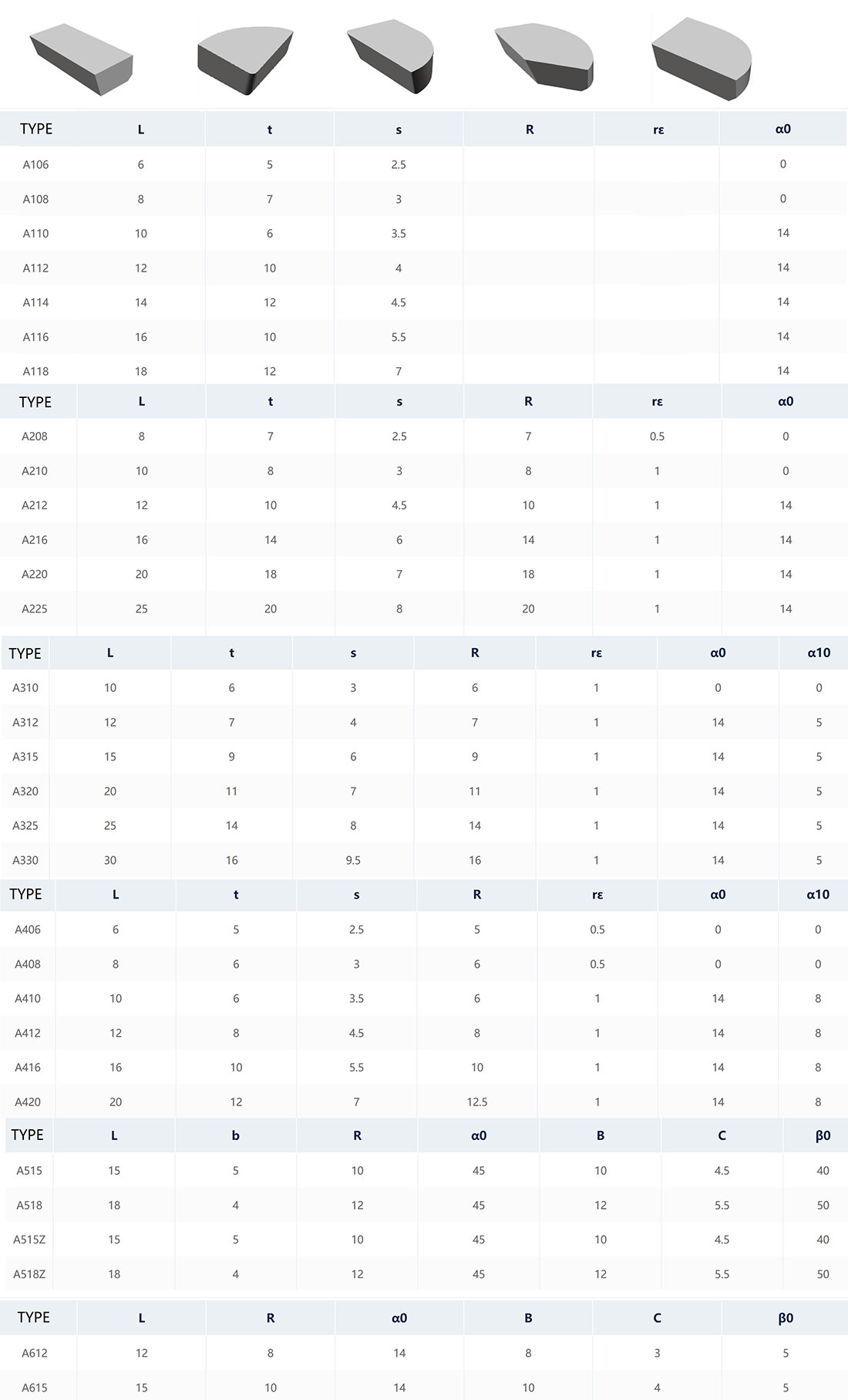

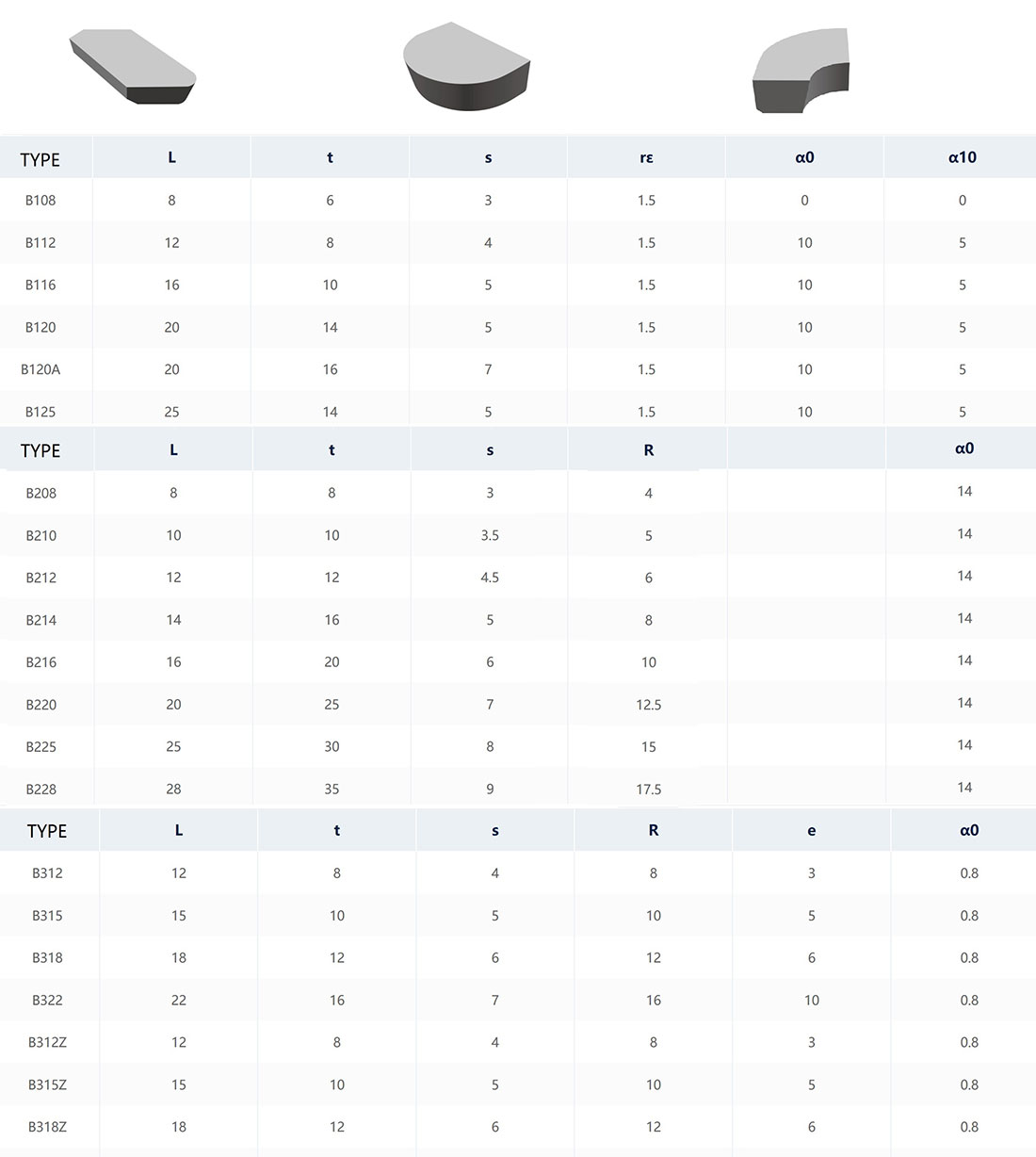

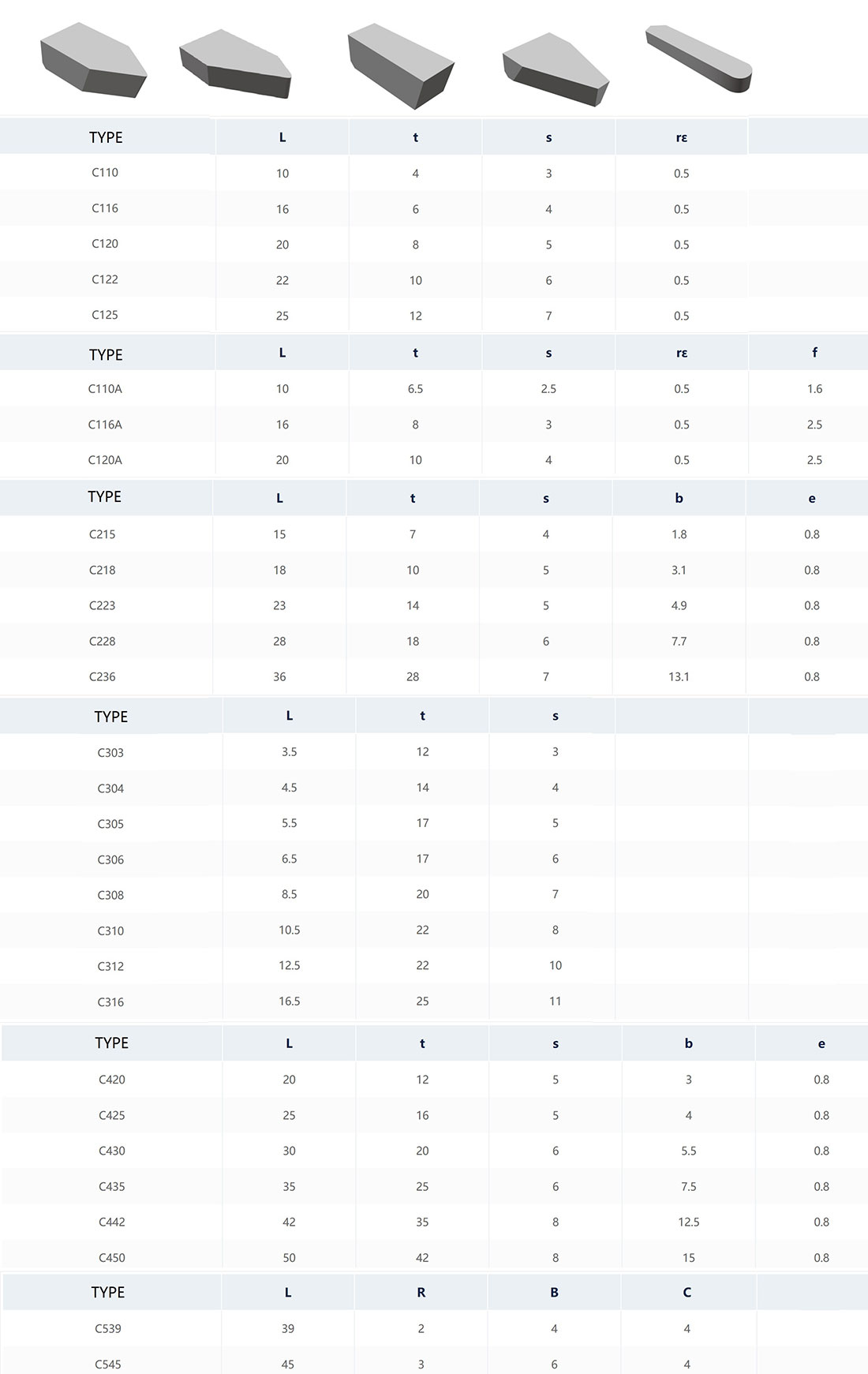

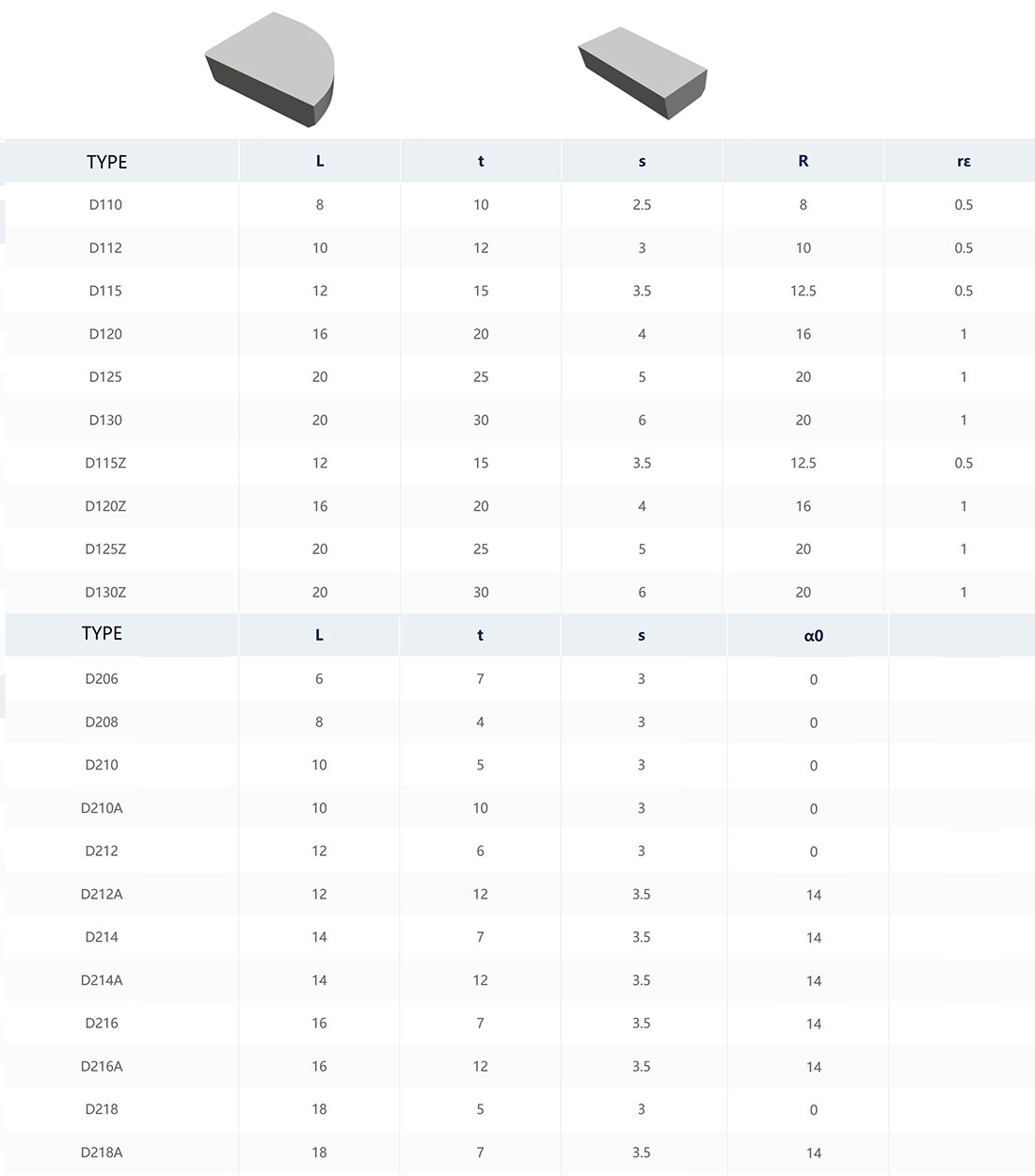

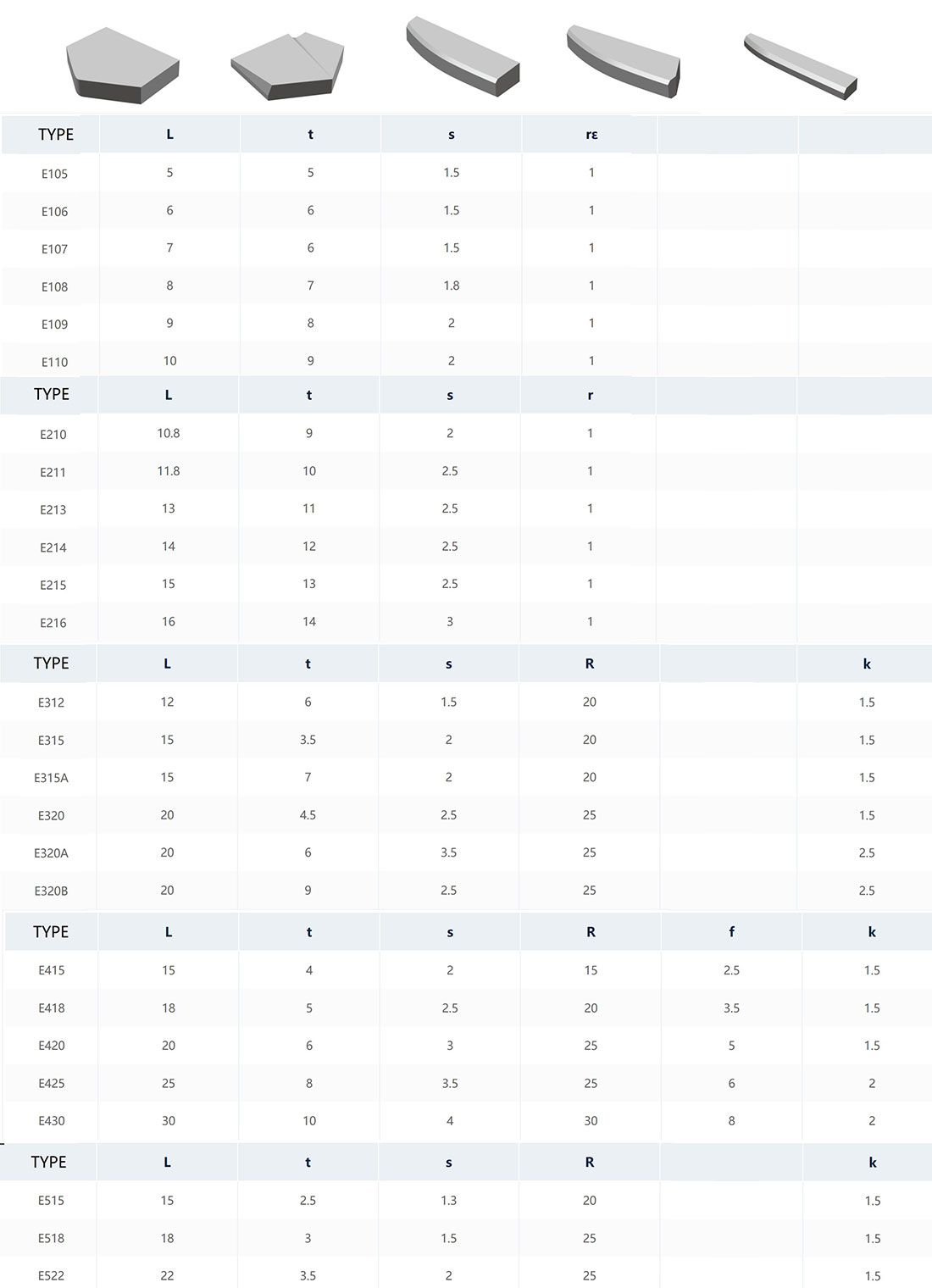

Standards sizes are available, such as A1 / A2 / A3 / A4 /A5 / A6 / A7 …… B1 / B2 / B3 / B4 / B5 / B6…., C1 / C2 / C3 / C4 / C5 / C6 / C8 / C10 …... D3 / D4 / D5 / D6 / D8 / D10 / D12 …. E4 / E5 / E6 / E8 / E10 /E12 / E16 …… F10 / F13 / F 16 / F20 / F25 / F60 …... G8 / G10 / G12 / G16 / G20 / G25 / G30…... and so on. And OEM shape and size are also available, you can give us your drawing, we will check it for you.

| Grade | ISO | Density (g/cm3) | Hardness(HRA) | T.R.S.(N/mm2) | Application |

| YT5 | P30 | 12.9 | 90.5 | 2200 | Best strength, high impact and shock resistance among W-Co-Ti alloys, but comparatively lower wear resistance. Suitable for rough turning, rough planning, and semi-finish planning of carbon steel, and alloy steel including forgings, stamped parts, and cast iron surfaces during intermittent cutting. |

| YW1 | M10 | 13 | 92.5 | 1710 | Better hardness, resistant to impact load. A good grade for general purposes. Suitable for machining of ordinary steel, cast irons as well as steels hard to be machined such as refractory steel, high manganese steel, and stainless steel, etc |

| YW2 | M20 | 12.9 | 91 | 1880 | Higher wear resistance and strength, resistant to high impact load. Suitable for roughing and semi-finishing of ordinary steel, and cast irons as well as refractory steel, high manganese steel, and high-grade alloy steel, etc |

| YG6X | K10 | 14.8 | 91.5 | 1890 | Fine grain WC alloy, wear resistance higher than YG6, strength close to YG6. Suitable for machining chilled alloy cast irons, and refractory alloy steel, as well as finishing of ordinary cast irons |

| YG6 | K20 | 14.8 | 89.5 | 2050 | High wear resistance, better impact and shock resistance. Suitable for semi-finishing, and finishing of cast irons, non-ferrous metal, alloys, and non-metallic materials at moderate cutting speed |

| YG8 | K30 | 14.6 | 89 | 2520 | High strength, better impact and shock resistance, but lower wear resistance and cutting speed. Suitable for roughing of cast irons, non-ferrous metal, alloys, and non-metallic materials at low speed. |

| YG11C | 14.4 | 86.5 | 2450 | Chiefly for the inserts and buttons of heavy rock drill bits and rotary-percussive bits, coal-cutting bits and tricone bits to cut medium-hard and hard formations. | |

| YG15 | 14.0 | 86.0 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations. | |

| YG20 | 13.5 | 85 | 2600 | Mainly for the stamping dies used in the conditions of heavy impact load and large stress | |

| YT15 | P10 | 11.3 | 92 | 1650 | Higher wear resistance with a certain impact toughness, Suitable for semi-finishing of medium chip sections, or finishing of small chip sections of steel, cast steel, alloy steel. |

Widely used in the cutting tools.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.