The tungsten carbide button is sintered by coarse grained powder, with properties of high hardness and good transverse-rupture strength, as well as corrosion resistance, resistance to acid and alkali.

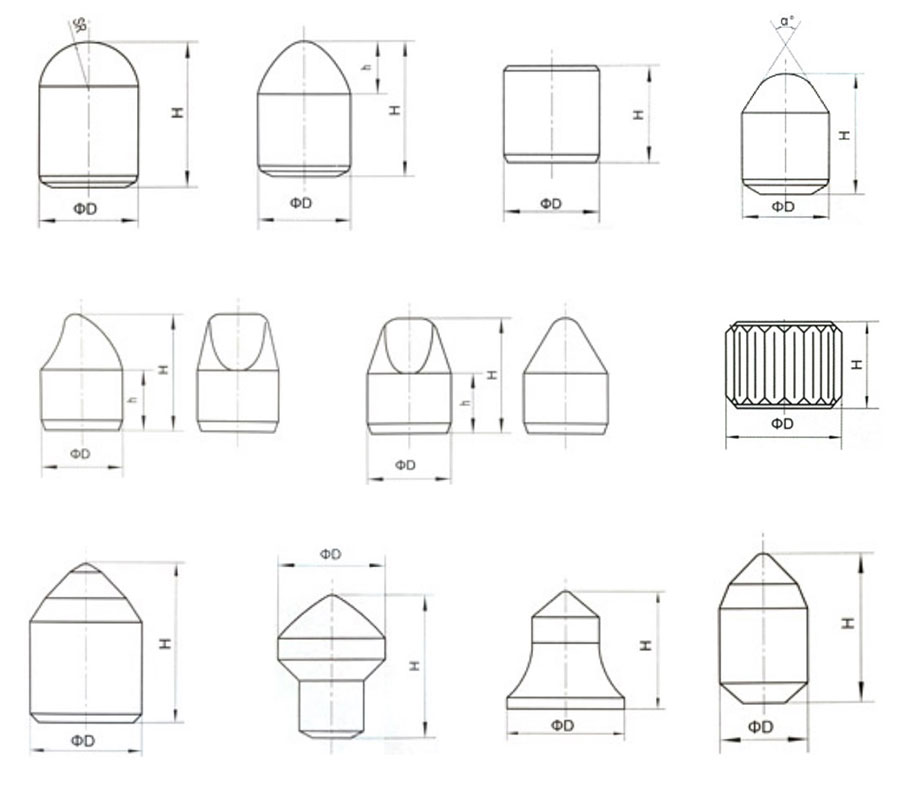

Our durable carbide buttons with excellent fracture resistance dramatically improve tool life with high penetration rates. The consistent performance and tolerance are mainly attributed to our pure raw materials and strict ISO quality control. All of our carbide buttons are made from virgin raw materials and HIP sintered for the top good quality and high performance. There are various sizes and styles are available here and we can also make the buttons in any new design to meet our customers' requirement.

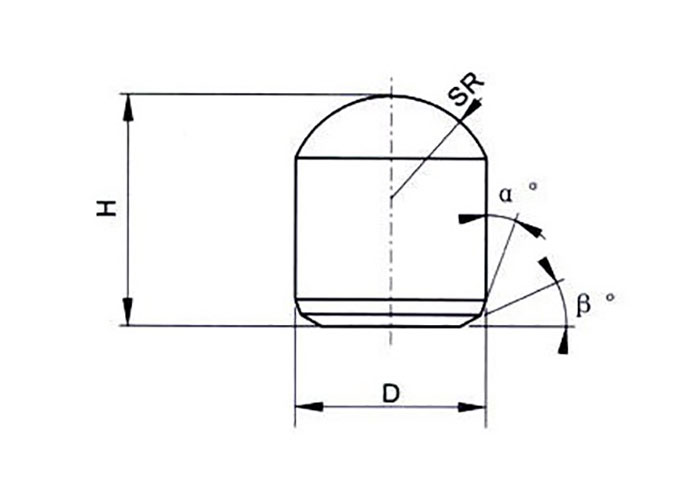

| Dimension (mm) | ||||

| D | H | SR | e | ɑ° |

| 8.25 | 10 | 4.4 | 1.5 | 18 |

| 8.25 | 12 | 4.4 | 1.5 | 18 |

| 18.25 | 27.1 | 9.2 | 1.5 | 18 |

| 8.25 | 12.2 | 4.4 | 0.7 | 30 |

| 9.25 | 14.9 | 5 | 0.7 | 30 |

| 10.25 | 13 | 5.5 | 0.7 | 30 |

| 11.3 | 14 | 6 | 0.7 | 30 |

| 12.35 | 16 | 6.6 | 0.7 | 30 |

| 13.35 | 18 | 7 | 0.7 | 30 |

| 14.35 | 18.1 | 7.7 | 0.7 | 30 |

| 16.35 | 24.6 | 8.8 | 0.7 | 30 |

| 20.45 | 30 | 11.5 | 0.7 | 30 |

| 22.45 | 30 | 12 | 0.7 | 30 |

| Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPa) | Application recommended |

| YG6 | 14.95 | 90.5 | 1900 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

| YG8 | 14.8 | 89.8 | 2800 | Used as a core drill, electric coal drill, coal cutter tooth, oil roller bit and scraper button bit. |

| YG8C | 14.8 | 89.8 | 2800 | Mainly used for small and medium-sized drill bit tooth, and as a rotating exploration drill bush. |

| YG11C | 14.4 | 86.5 | 2700 | Most used in the drill bit and rock bit used for cutting high hardness materials ball tooth. |

| YG13C/YK40 | 14.2 | 86 | 2900 | mainly used for rotary drill bit used for cutting high hardness materials in ball mill. |

| YG15C | 14 | 85 | 3000 | Used in oil cone bit and soft in the hard rock digging cutting tools. |

| YK05 | 14.9 | 90.5 | 2600 | Mostly used as the buttons of small and medium sized bits to cut soft and medium hard formations |

| YK15 | 14.6 | 88 | 2750 | Suitable to strips, conical buttons for rotary percussion-resistant geological prospecting buttons, cut soft and medium hard formations. |

| YK20 | 14.5 | 87.5 | 2800 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and very hard formations, |

| YK25 | 14.4 | 87.2 | 2550 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard, hard, and very hard formations |

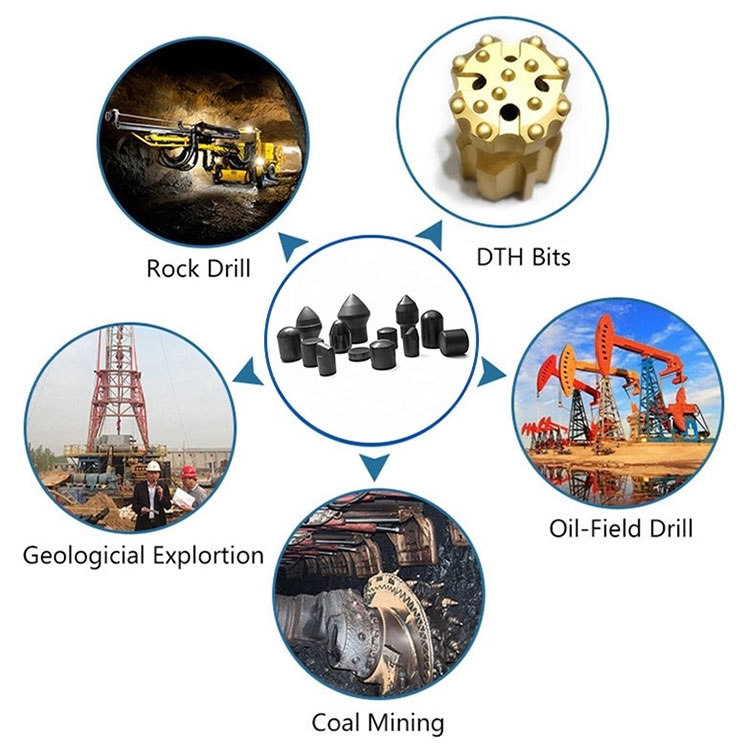

Button bits for coal mining

These tungsten carbide button bits are mainly used for coal mining, coal cutting picks, electric coal drill bits, coal mining cutter picks, roadway excavation, rotary drilling for pile hole, pavement milling. Such as Bob's bit, Rotary bit, Digger button bit and so on.

Carbide button bits for construction

Such carbide button bits are mainly used for bridge pile foundation excavation, tunnel shield, urban road crossing, mining wear parts, high-speed railway, highway maintenance and the like. These products are complex in specification, with wide range of applications, stable and reliable quality.

Carbide button bits for oil-field

This carbide button bits are mainly used for tri-cone drill bits for oil and gas fields excavation and large-scale open-pit mine. And they are made into Tricone bit, PDC bit, horizontal directional drilling system(HDD),with excellent product stability, ensuring the safety and reliability of deep mining.

Mining button bit

These products are mainly used for high and low pressure DTH drill and hydraulic screw-in drill and so on, suitable for hot insert or cold pressing bit inserting process, with some of the materials used in the welding process. These bits are made into DTH hammer Anchor bit, Top hammer, Cluster hammer, and so on.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.