Tungsten Carbide Rod is mainly made of WC and Co by powder metallurgic method processing. They have a good shock resistance and bending resistance. With more than 20 years’ experience, we are able to provide you the carbide rods you want.

| WC Grain size range | 0.3~0.5μ.m; 0.5~0.9μ.m; 1.0~1.3μ.m; 1.4~2.0μ.m. |

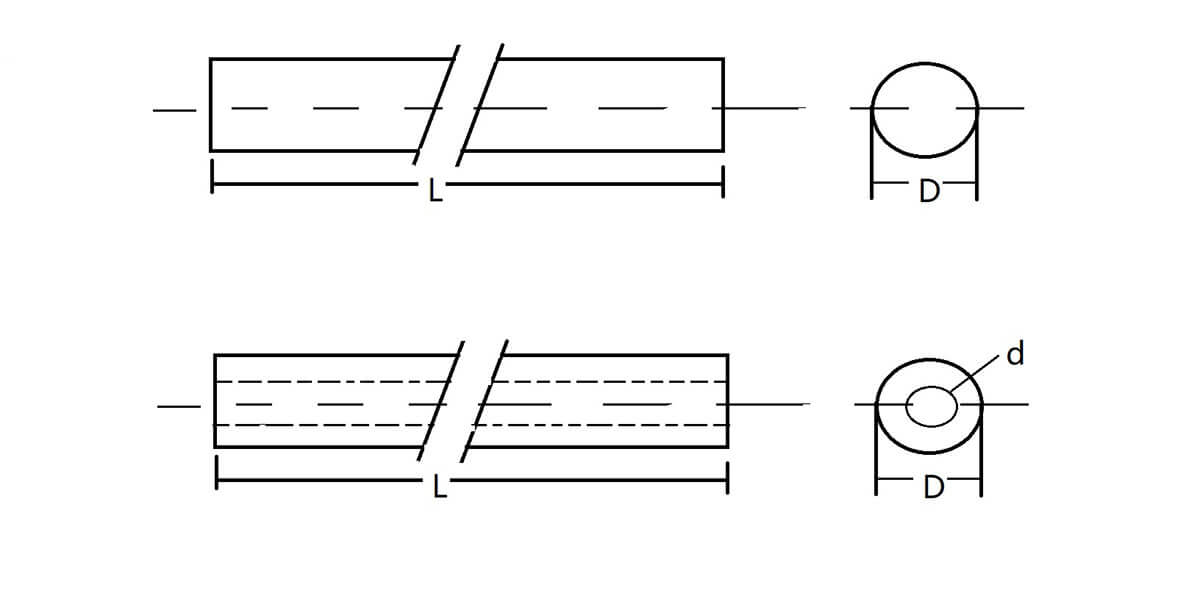

| Diameter range | 0.33mm--60mm |

| Length range | 3mm--1000mm; |

| Diameter Grade | h4(H4), h5(H5), h6(H6), h7(H7), h8(H8), h9(H9). |

| Surface Roughness | Polished Ra 0.04 or unpolished |

| Remarks | OEM acceptable |

| Grade/ Properties / Application | |||||

| Grade | Equal to ISO Category Number | Performance | Performance&application recommended | ||

| Density | Bend Strength | Hardness | |||

| G/Cm 3 | N/mm 2 | HRA | |||

| YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | |

| YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG8 | K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| YG10X | 14.5 | 2400 | 91.5 | Fine grain alloy, good wear resistance,Used for processing hard | |

| wood, veneer board,PCB,PVC and metals. | |||||

| YL10.2 | 14.5 | 2400 | 91.8 | Forming or stamping dies for metal powders and nonmental powders. | |

| YG13X | 14.3 | 2600 | 89.5 | For oil cone dril bits, for medium soft and medium-hard rocks. | |

Various carbide grades with stable properties have been widely recognized by worldwide makers of tools. Tungsten carbide rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel-based alloy, titanium alloy, and nonferrous metals. They are widely used for HSS Cutting tool, carbide end mills, carbide cutting tool, NAS cutting tool, aerospace cutting tool, carbide drills, pilot reamer, electronics cutter, step drill, metal cutting saw, carbide burrs, carbide tipped cutter etc.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.