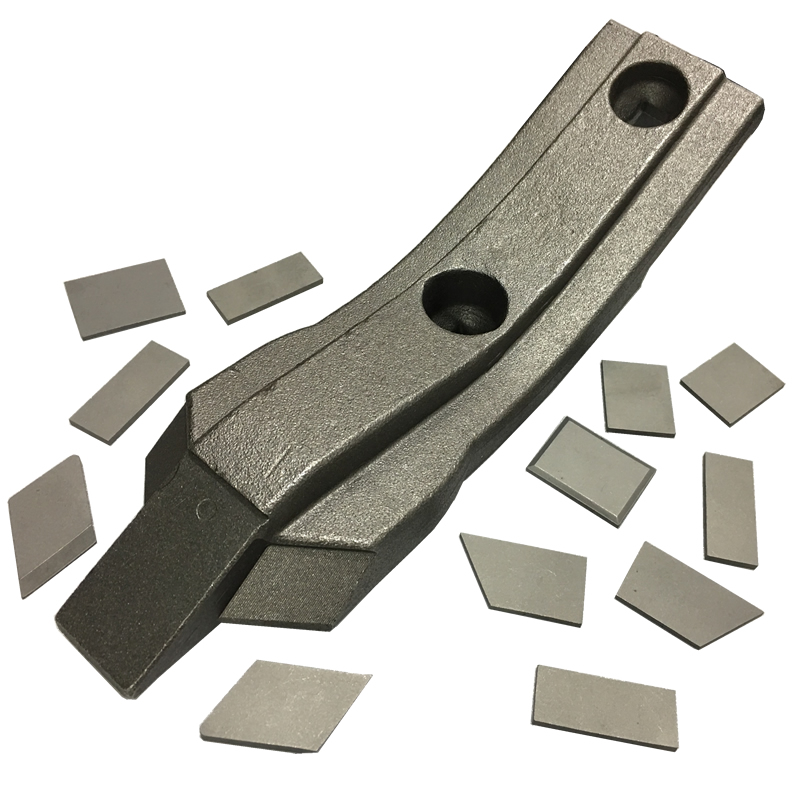

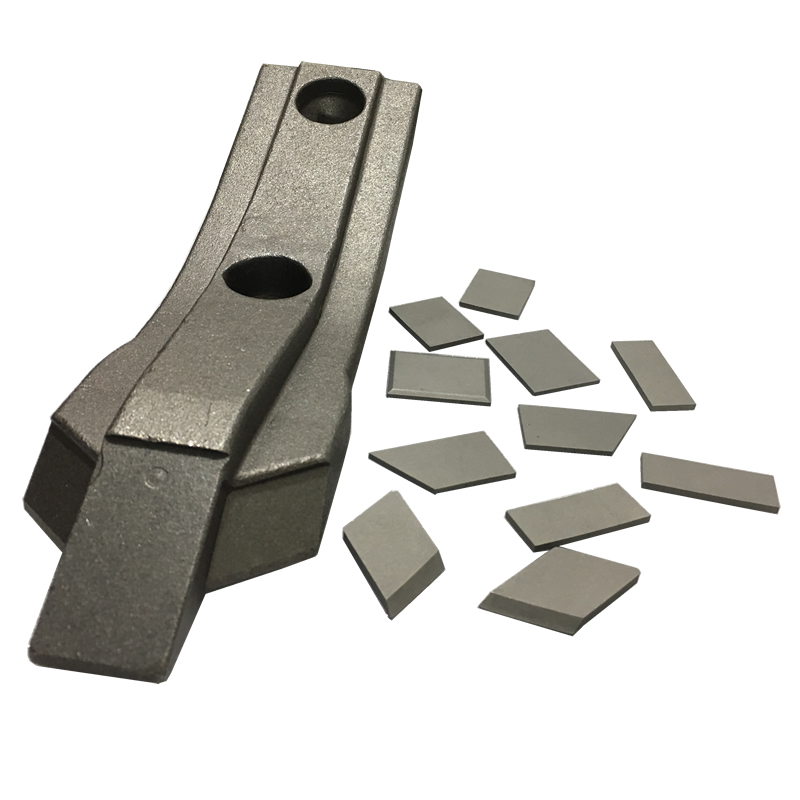

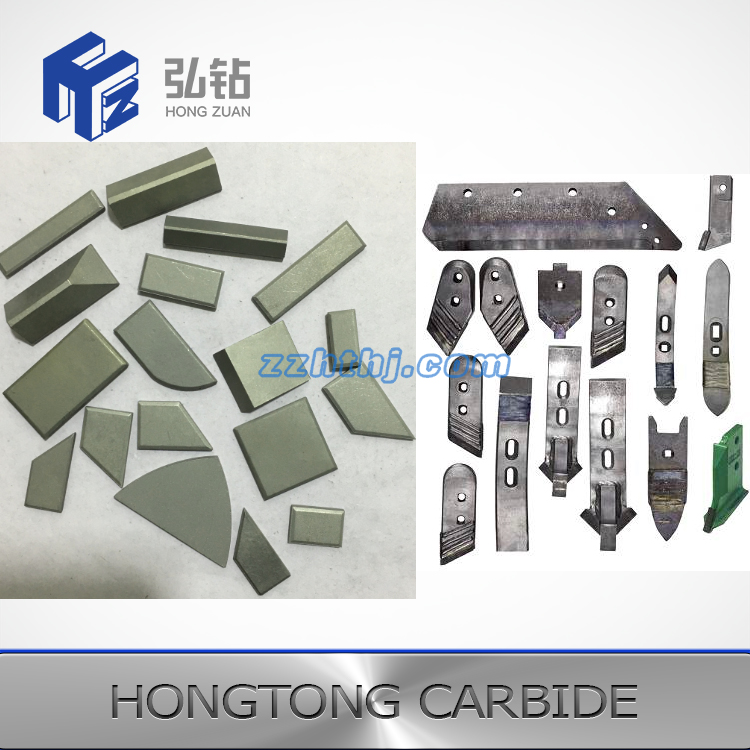

Tungsten carbide has the characters of high wear resistance and good compressive properties, so it’s widely used in many different industries which requires high wear resistance. For the agriculture industry, the machinery uses various kinds of wear parts, which are replaceable frequently. If the parts’ life time is longer, the cost will be much lower. More and more people are welding carbide tips to the casting to make agricultural wear parts, then the lifetime can be 5-10 times than the parts without carbide.

| Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPa) | Application recommended |

| YG6 | 14.95 | 90.5 | 1900 | For agricultural wear parts which not facing heavy impact. |

| YG8 | 14.8 | 89.8 | 2800 | For agricultural wear parts which not facing heavy impact. |

| YG8C | 14.8 | 89.8 | 2800 | For agricultural wear parts which facing middle impact. |

| YG11/YG11C | 14.4 | 86.5 | 2700 | For agricultural wear parts which facing middle impact. |

| YG13/YG13C | 14.2 | 86 | 2900 | For agricultural wear parts which facing light impact. Hardness will not be high. |

| YG15/YG15C | 14 | 85 | 3000 | For agricultural wear parts which facing light impact. Hardness will not be high. |

There are so many different kinds of agricultural machinery in the world, carbide is widely used in this industry, such as cultivation machinery, soil preparation machinery, subsoil machinery, plough machinery, plowing machinery, harvest machinery, and so on. Almost every agricultural machinery brand and most of the agricultural parts will use carbide to get better quality and longer lifetime.

As a professional tungsten carbide manufacturer from China, with more than 20 years’ experience, we have skilled engineers and technical know-how, to meet any of your carbide request.